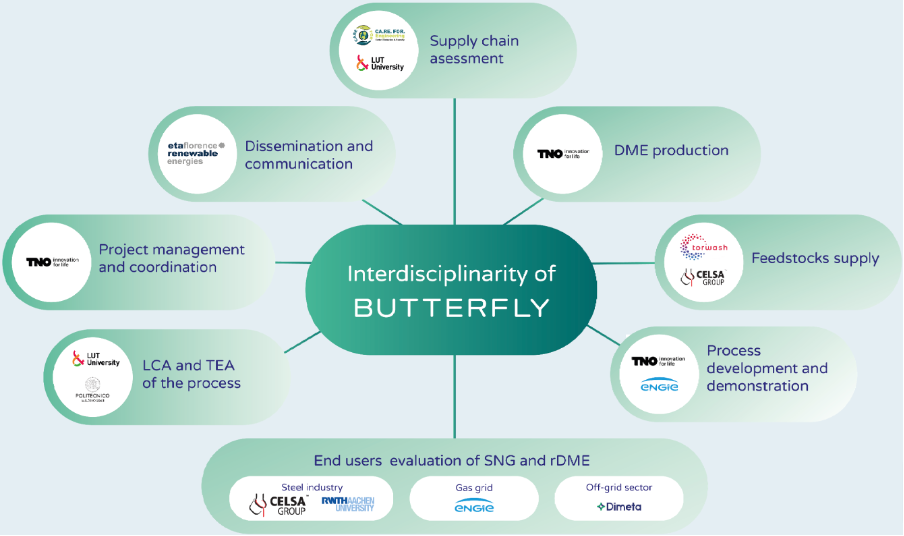

The Butterfly Project, led by TNO and funded by the European Commission’s Horizon Europe programme, is an exciting collaboration that brings together a consortium of eleven partners from seven different EU countries, including Dimeta, TNO, ENGIE, Politecnico di Milano, LUT University, CA.RE.FOR Engineering, CELSA GROUP, TORWASH, ETA Florence Renewable Energies, RWTH Aachen University, and BARNA Steel.

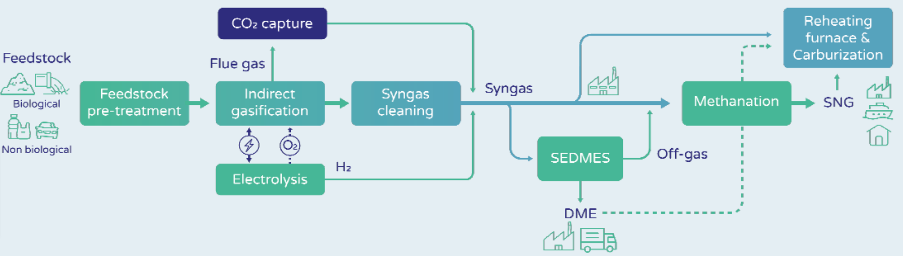

The project aims to deliver a circular, cost-effective and flexible production process of renewable and recycled carbon fuels. The project will pioneer an innovative co-production process using cutting-edge technologies harnessing the potential of sustainable biogenic and non-biogenic feedstocks to produce renewable and recycled carbon dimethyl ether (DME) and Synthetic Natural Gas (SNG). The project integrates ENGIE’s Gaya gasification plant in France with TNO’s Sorption Enhanced DME Synthesis technology (SEDMES); the project targets the off-grid energy supply, the steel industry and the heavy transportation sector.

We spoke with Katrien Wijsman, Business Development Director at Dimeta, and Jurriaan Boon, Senior Scientist Process Technology at TNO, to learn more about the Butterfly project.

Can you talk to us about you and your role?

Jurriaan Boon: My name is Jurriaan Boon, and I am a chemical engineer at TNO, based in Petten, the Netherlands. At TNO, I focus primarily on process intensification technologies for carbon dioxide (CO2) capture and conversion reactions. This encompasses a wide range of topics related to CO2 capture and various aspects of CO2 conversion.

One area in which we excel at TNO is using separation enhancement techniques within process intensification. This involves introducing adsorbents or membranes into the chemical reactor, which improves reactor performance. We have successfully applied this approach to numerous CO2 conversion technologies, including the synthesis gas to methanol process and, particularly, renewable DME production.

I am passionate about our work at TNO, which allows us to contribute to global efforts to combat climate change and transition towards a more sustainable future.

Katrien Wijsman: I am Katrien Wijsman, Business Development Director at Dimeta. I joined Dimeta in July 2023, transitioning from SHV Energy. In this role, I work closely with my team to facilitate ongoing projects that focus on scaling the production of renewable and recycled carbon DME. This involves actively engaging with technology providers and various partners to initiate projects that develop the production of renewable and recycled carbon DME in Europe and the US.

What is the Butterfly project, and what overall goals do you aim to achieve?

B.J.: The Butterfly Project is an innovative initiative that aims to utilize cutting-edge technologies to co-produce renewable DME and Synthetic Natural Gas (SNG) from sustainable biogenic and non-biogenic feedstocks.

The project will utilize the existing GAYA gasifier from one of the partners located in France, which is currently focused on producing SNG, and the Sorption Enhanced DME Synthesis (SEDMES) technology, developed by TNO, which is focused on producing DME.

The project’s primary objective is to demonstrate the flexible co-production of SNG and DME by placing the SEDMES technology downstream of the gasifier. The SEDMES can convert a certain amount of the synthesis gas produced in the gasifier into DME. This introduces flexibility in the conversion of DME, ensuring that any residual synthesis gas that is not converted into DME can be efficiently converted to SNG.

What makes this approach truly significant is that it grants plant operators the ability to make various product choices within a single process, also depending on market conditions and demands. Additionally, it enables them to experiment with different feedstocks and explore the incorporation of green hydrogen into the process. By incorporating green hydrogen, synthetic DME or SNG production capacity can be increased even further.

The Butterfly Project aims to revolutionize the energy sector by creating a more sustainable and flexible production process that allows for greater market and resource availability adaptability.

What is the role of Dimeta in the butterfly project? What is the importance of the project in decarbonizing the off-grid energy sector?

K.W.: Dimeta leads the development of the adoption and use of renewable and recycled carbon DME. Therefore, Dimeta leads a work package within the Butterfly project, with a focus on assessing market identification and technology exploitation. This involves identifying value chains and applications, conducting market assessments, and developing business plans for the two main project products: DME and SNG. Additionally, Dimeta contributes to various other tasks and work packages, including defining technical specifications for DME storage and quality requirements for DME.

Moreover, Dimeta is particularly focused on developing DME production and its use in the off-grid energy sector. Therefore, Dimeta is committed to supporting the development and evaluation of potential pathways to DME production that can contribute to decarbonization efforts. The Butterfly project is instrumental in this pursuit as it allows for further testing of the SEDMES technology, thereby facilitating sustainable routes for DME production.

How was the consortium selected, and how will the project as a whole advance the development and commercial demonstration of renewable DME?

B.J.: The Butterfly project involves an interdisciplinary consortium of truly innovative partners selected based on their technical and business expertise. From a technical standpoint, TNO and ENGIE lead the process development and scale-up efforts. The goal is to advance the synthesis technology for renewable DME and bring it to Technology readiness level (TRL) 7 by demonstrating its operational viability downstream of the biomass gasifier.

The consortium has diverse participants who bring a wealth of experience to the project. For example, Dimeta focuses on DME applications in the off-grid sector, while another consortium member primarily focuses on synthetic natural gas applications. Additionally, companies and research institutes are involved in exploring DME applications in the steel industry. This approach allows the project to target multiple outlets for DME products and consider various feedstock options.

The project also involves partners contributing to essential aspects such as supply chain assessments, life cycle analysis, techno-economic analysis, and system optimization. These efforts ensure that the project considers the entire lifecycle of the technology, its economic viability, and optimal performance. Notably, the project intends to de-risk large-scale demonstration through lab-scale R&D modelling and implement a digital twin of the conversion process controlled by artificial intelligence (AI). This will aid in optimizing the process and accelerating the development and application of the technology.

The Butterfly concept is complex, as it involves targeting multiple feed streams and outlet products based on market responses and demand flexibility. By leveraging AI applications, the project aims to control better and optimize this complex process, surpassing what would be possible without such technologies.

Through the consortium’s collaboration and comprehensive approach, the Butterfly project is well-positioned to advance the development and commercial demonstration of renewable DME and address technical, business, and market challenges.

“Through the consortium’s collaboration and comprehensive approach, the Butterfly project is well-positioned to advance the development and commercial demonstration of renewable DME and address technical, business, and market challenges”.

Jurriaan Boon, Senior Scientist Process Technology, TNO

How does this partnership fit into Dimeta’s overall plan to advance the adoption of Renewable and recycled Carbon DME?

K.W.: As Dimeta operates across the entire value chain, any project that supports the development of renewable and recycled carbon DME is highly relevant and significant for us and our partners. We eagerly seek collaborations with industry associates actively involved in this field. Being part of the Butterfly consortium allows us to participate and contribute to key initiatives that drive the advancement of DME. We are proud to be part of the Butterfly consortium and contribute our expertise to the project.

Can you explain briefly how the TNO SEDMES technology produces renewable DME and what makes it innovative?

B.J.: TNO’s SEDMES technology is an innovative renewable fuel and feedstock production process. Unlike conventional technologies, SEDMES offers a single-step process that directly converts synthesis gas into DME. This simplifies the overall production process and provides a high level of flexibility.

Traditionally, different feedstocks require specific treatment due to variations in their composition. However, SEDMES can handle diverse feedstocks, such as hydrogen (H2) and carbon monoxide (CO) or hydrogen (H2) and carbon dioxide (CO2), without compromising the conversion efficiency. This means the technology can effectively and almost entirely convert both feedstock compositions into DME.

Among the innovative advantages of SEDMES is its flexibility. You no longer need to design and configure your plant for a specific feedstock composition. Instead, installations can be modified to accommodate different feedstock compositions or throughputs, providing significant operational freedom and adaptability. SEDMES enables the conversion of a wide range of feedstocks into renewable DME, including biogas, with the efficient conversion of CO2, CO, and hydrogen. This advances the development and utilization of DME as a sustainable energy source.

Being part of the Butterfly consortium allows us to participate and contribute to key initiatives that drive the advancement of DME. We are proud to be part of the Butterfly consortium and contribute our expertise to the project.

Katrien Wijsman, Business Development Director